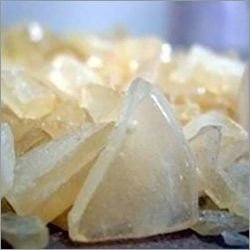

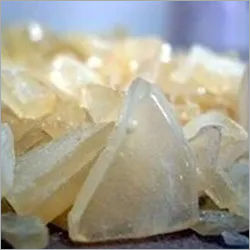

Alkyl Phenolic Resin

Alkyl Phenolic Resin Specification

- Type

- Alkyl Phenolic Resin

- CAS No

- 9003-35-4

- EINECS No

- 232-023-1

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Application

- Adhesives, Coatings, Rubber Compounding, Printing Ink, Varnishes

- Color

- Yellow to Amber

- Form

- Solid

- Compatibility

- Compatible with natural and synthetic rubbers

- Viscosity

- Dependent on application

- Storage Condition

- Store in a cool, dry place

- Molecular Weight

- Varies (typical range 300 - 24,000)

- Shelf Life

- 2 years

- Softening Point

- 90 105C

- Solubility

- Soluble in Organic Solvents

- Melting Point

- Above 100C

- Packaging

- 25 kg Bags or as required

- Odor

- Characteristic phenolic odor

Alkyl Phenolic Resin Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash in Advance (CID)

- Supply Ability

- 5000 Kilograms Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Alkyl Phenolic Resin

By keeping track of the latest industry developments, we are engaged in offering a wide range of Alkyl Phenolic Resins that are commonly used in rubber industries. The offered resins are processed using the finest grade chemical compounds and modern technology in accordance with the set industry standards. The offered resins are also verified on various quality parameters to ensure their premium quality. Moreover, our offered resins can be availed by our clients at effective cost

Alkyl Phenolic Resin Features:

- Heat resistant

- High performance

- Reliability

Description:

| Sr. No | Grade No. | Description |

| 1 | KAP-101 | Alkyl Phenol Formaldehyde Resin Used in Neoprene Rubber Based Adhesive |

| 2 | KAP-102 | Used to Gain Improvement in Chemical & Physical Properties of Butyl Rubber Resulting from Sulfur Vulcanization |

| 3 | KAP-103 | Useful to Produce Highly Viscous Unvulcanized Rubber Mixtures for Manufacturing Tyres, Remoulding Material, Conveyor Belts, Lining Material, etc. |

| 4 | KAP-104 | Alkyl Phenol Formaldehyde Resin Used in Neoprene Rubber Based Adhesive |

| 5 | KAP-106 | Alkyl Phenol Formaldehyde Resin Used in Neoprene Rubber Based Adhesive. It has high heat resistant properties |

Superior Compatibility and Versatility

Alkyl Phenolic Resin exhibits remarkable compatibility with a wide range of natural and synthetic rubbers. Its adaptability ensures optimal blending in diverse industries, notably in the production of adhesives, coatings, rubber compounds, printing inks, and varnishes. This versatility makes it a preferred choice for manufacturers seeking resilient, high-performing resins.

Reliable Performance Under Various Conditions

With a softening point of 90105C and a melting point above 100C, this resin performs consistently even under demanding thermal environments. Its solubility in organic solvents further broadens its application scope, facilitating effortless mixing and incorporation into various industrial processes.

Safe Storage and Convenient Packaging

Supplied in 25 kg bags, Alkyl Phenolic Resin is easy to handle and store, with a recommended shelf life of two years in cool, dry conditions. The products solid form and characteristic odor ensure safety and straightforward usage for manufacturers and suppliers.

FAQs of Alkyl Phenolic Resin:

Q: How should Alkyl Phenolic Resin be stored to maintain its quality?

A: To preserve the resins properties and ensure a full shelf life of up to two years, it should be stored in a cool, dry place away from direct sunlight and moisture. Proper storage helps prevent degradation and contamination.Q: What are the primary industrial applications of Alkyl Phenolic Resin?

A: This resin is extensively used in adhesives, coatings, rubber compounding, printing ink, and varnish formulations. Its unique properties, such as high purity and compatibility, make it suitable for a variety of industrial processes.Q: When is Alkyl Phenolic Resin most beneficial in rubber compounding?

A: The resin is especially beneficial during mixing and processing stages where enhanced compatibility and improved mechanical properties are required, such as in high-performance industrial rubber goods and adhesives.Q: Where can Alkyl Phenolic Resin be applied for optimal results?

A: Optimal results are achieved in environments and products demanding thermal stability and solvent solubility, such as manufacturing adhesives, specialty rubbers, industrial inks, and protective coatings.Q: What advantages does Alkyl Phenolic Resin offer over conventional resins?

A: It delivers superior compatibility with various rubber types, notable thermal stability, and a high purity level (99%), enabling consistent performance across applications. Its versatility in both natural and synthetic rubber-based systems is a significant benefit.Q: How is Alkyl Phenolic Resin typically used in adhesive formulations?

A: It is blended with rubber or other polymers to improve adhesive strength, tack, and heat resistance. Its solubility in organic solvents allows for easy incorporation during the mixing stage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alkyl Phenolic Resin Category

Solid Alkyl Phenolic Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Purity(%) : 99%

Color : Yellow to Light Brown

Type : Other, Solid Alkyl Phenolic Resin

Grade : Industrial Grade

Alkyl Phenolic Resins

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Purity(%) : 98%

Color : Brown

Type : Other, Alkyl Phenolic Resin

Grade : Industrial Grade

Alkyl Phenolic Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Purity(%) : 99%

Color : Brown

Type : Other, Alkyl Phenolic Resin

Grade : Industrial Grade

Phenolic Alkyl Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Purity(%) : 99%

Color : Yellow to Light Brown Granule

Type : Other, Phenolic Alkyl Resin

Grade : Other, Industrial

GST : 27AACCK7123R1Z1

|

KANORIA CHEMBOND PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry