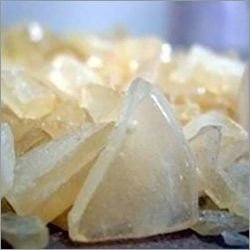

Alkyl Phenolic Resin

Alkyl Phenolic Resin Specification

- Type

- Alkyl Phenolic Resin

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Application

- Adhesives, Coatings, Rubber Compounding, Paints

- Color

- Brown

- Form

- Solid Granules

Alkyl Phenolic Resin Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Payment Terms

- Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Alkyl Phenolic Resin

Versatile Applications Across Industries

Alkyl Phenolic Resin serves as an essential raw material for various industries. Its strong adhesive qualities make it ideal for adhesives and rubber compounding, while its chemical stability enhances the performance of paints and coatings. This versatility allows manufacturers to improve finished product quality and extend durability, catering to both local and global industrial demands.

Strict Quality Assurance

Sourced and processed in India, our Alkyl Phenolic Resin undergoes stringent quality checks to guarantee 99% purity. Our manufacturing processes follow rigorous standards, ensuring each batch meets the specific requirements of industrial applications. As a reliable exporter, we focus on delivering consistent quality, tailored packaging, and timely shipments for all our customers.

FAQs of Alkyl Phenolic Resin:

Q: What are the main applications of Alkyl Phenolic Resin in industry?

A: Alkyl Phenolic Resin is widely used in adhesives, coatings, rubber compounding, and paints to enhance binding, durability, and chemical resistance. Its industrial-grade formulation ensures optimal performance in these sectors.Q: How is Alkyl Phenolic Resin typically processed and supplied?

A: This resin is manufactured in solid granule form, ensuring ease of handling and uniform mixing in production processes. It is packed according to client requirements and dispatched as per bulk industrial orders.Q: When is Alkyl Phenolic Resin the ideal choice for manufacturing?

A: The resin is most suitable when high-purity binding and durability are required, especially in heavy-duty adhesive, rubber, or coating formulations. Its performance excels in applications demanding chemical and thermal stability.Q: What benefits does Alkyl Phenolic Resin offer for adhesives and rubber compounding?

A: It provides superior adhesive strength, enhances elasticity and resilience in rubber products, and resists degradation, leading to longer-lasting end products with improved performance.Q: Where is your Alkyl Phenolic Resin produced and do you export internationally?

A: Our resin is produced in India under stringent quality control. As an exporter, manufacturer, and supplier, we serve both domestic and international markets, ensuring reliable global distribution.Q: How should Alkyl Phenolic Resin be stored and handled for optimal results?

A: Store the resin in cool, dry conditions away from direct sunlight and moisture. Use standard industrial handling procedures to maintain its integrity and prevent contamination.Q: What is the process for ordering Alkyl Phenolic Resin in bulk quantities?

A: You can contact us directly with your specifications and required quantities. We provide technical support, customized packaging options, and efficient logistics to fulfill bulk orders for national and international clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alkyl Phenolic Resin Category

Solid Alkyl Phenolic Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Grade : Industrial Grade

Color : Yellow to Light Brown

Application : Adhesives, Rubber Industry, Coatings, Paints, Inks

Purity(%) : 99%

Alkyl Phenolic Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Grade : Industrial Grade

Color : Yellow to Amber

Application : Adhesives, Coatings, Rubber Compounding, Printing Ink, Varnishes

Purity(%) : 99%

Alkyl Phenolic Resins

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Grade : Industrial Grade

Color : Brown

Application : Adhesives, Rubber Compounding, Coatings, Paints

Purity(%) : 98%

Phenolic Alkyl Resin

Price Range 120.00 - 160.00 INR

Minimum Order Quantity : 500 Kilograms

Grade : Other, Industrial

Color : Yellow to Light Brown Granule

Application : Coating Industry, Paint, Paint Auxiliaries, Printing Ink, Varnish

Purity(%) : 99%

GST : 27AACCK7123R1Z1

|

KANORIA CHEMBOND PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry